Contact

Science Park

Gjuterigatan 9

553 18 Jönköping

+46 (0)36-33 20 820

contact@combiq.com

About Combiq

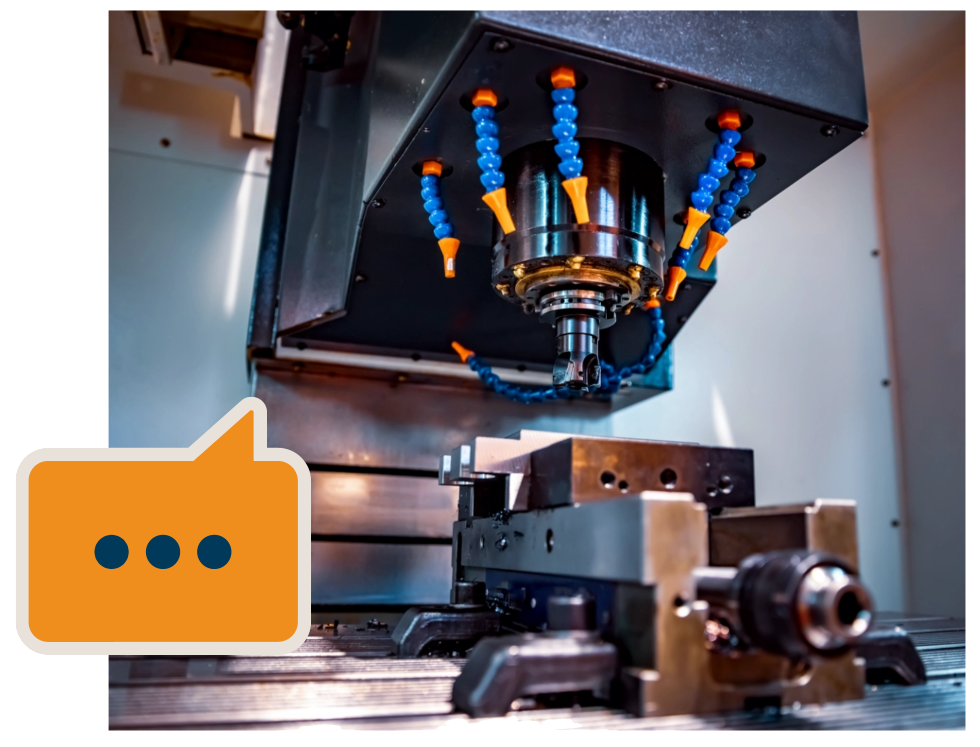

CombiQ delivers a complete toolbox for digital measurement and monitoring by mounting our proprietary smart sensors to your equipment, such as machines, devices, tools, or other assets.

Contakt

Science Park

Gjuterigatan 9

553 18 Jönköping

+46 (0)36-33 20 820

contact@combiq.com

About Combiq

We increase efficiency, reduce the risk and improves profits through automation and digitization of industrial companies. We deliver an overall solution for industrial Internet of Things where the electronics, cloud service and our collaboration with the customer make industry more efficiently and more profitable.